Hello everyone, I've made progress, but I'm struggling with some things.

I started with Dezsoe's macro, which works very well for me.

I added a counterclockwise spindle start. However, since the probing is done in two parts, the spindle stops right after the rapid probing. I haven't figured out how to maintain the rotation.

Second problem: I can't create an X- offset (I'm at the limit of X+ with my probe).

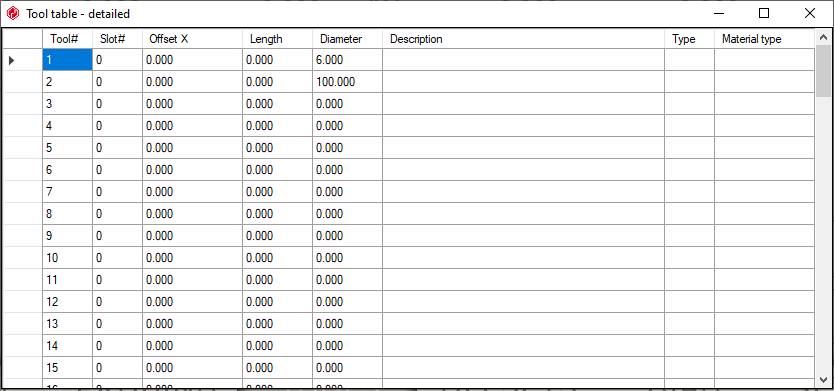

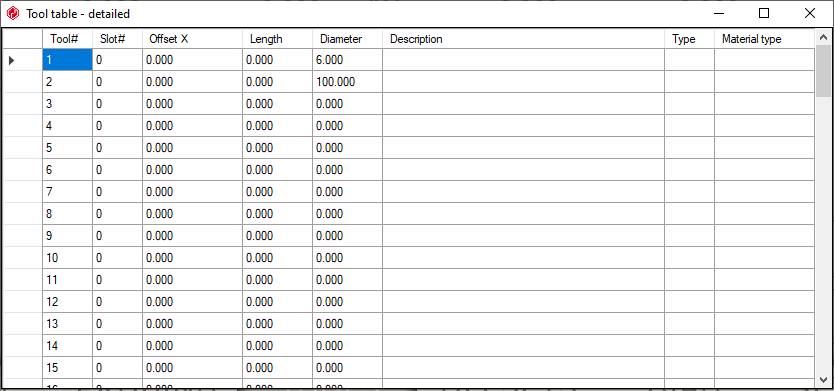

For the test, I have two tools: the first (T1) with a diameter of 6mm, the second (T2) with a diameter of 100mm, which I entered in the tool table.

I integrated a tool diameter reading box into the macro, but the reading does not correspond to the diameter recorded in the tool table, for example it gives me 1mm for T1 and 2mm for T2.

I realized that the tool field was not good, I added a tool field reading and in the UCCNC dialog box I had:

Do "Field 17" and "Field 18" correspond to tools T1 and T2?

If so, why don't they correspond to the respective diameters?

Here is a screenshot of the tool table;

I'm attaching the latest version of the macro, if anyone can help me see more clearly that would be great.