Units are inches

Here is a snip of the code:

Feed is set to 100 ipm

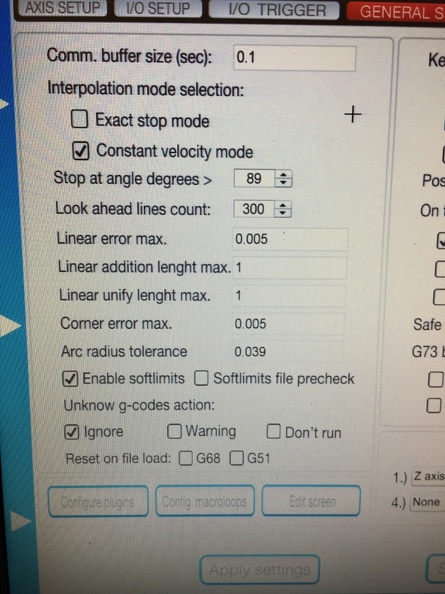

Screen shot of settings for this test:

- Code: Select all

N1 G20

N2 G0 G17 G40 G80 G90

N3 G64(CONSTANT CONTOUR OFF OR TURN ON W/G64)

N4 G54

N672 G01 X-12.0428 Y14.7786

N673 G02 X-11.9666 Y15.0742 I3.4524 J-0.7329

N674 G02 X-11.8121 Y15.5098 I3.8949 J-1.1364

N675 G02 X-11.6829 Y15.7905 I4.0958 J-1.7150

N676 G01 X-11.6589 Y15.8339

N677 G02 X-11.4733 Y16.1556 I3.5632 J-1.8406

N678 G02 X-11.3030 Y16.4013 I4.9988 J-3.2829

N679 G02 X-10.9968 Y16.7662 I3.7765 J-2.8585

N680 G01 X-10.8412 Y16.9228

N681 G01 X-10.7593 Y16.9981

N682 G01 X-10.6774 Y17.0716

N12457 M30

When it transitions from line 672 to 673 the feed drops from 100 ipm to 24 ipm. It also drops to like 42 ipm transitioning from 676 to 677

Here is a slow motion video of the screen:

https://youtu.be/YeyidvkZG1g

Is this how everyones machines are running? The tool path isn't that complicated.

Thanks

Derek